Geothermal Development

:::

Geothermal Development menu switch

Geothermal Development

:::

Background

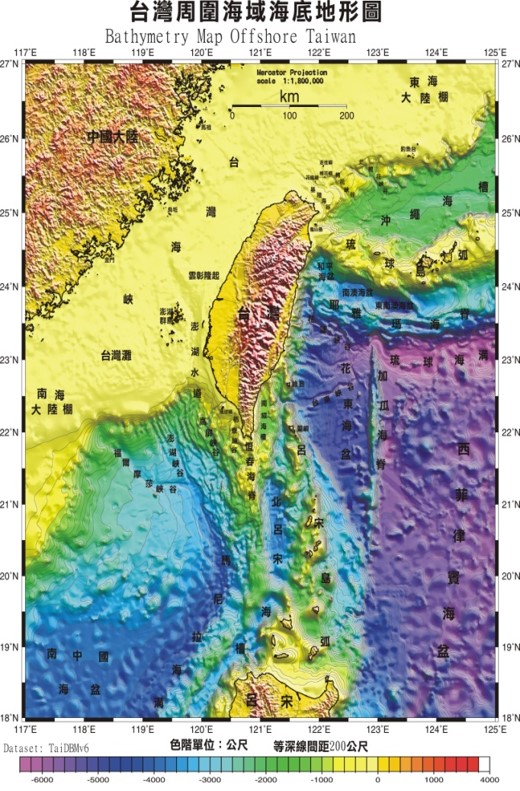

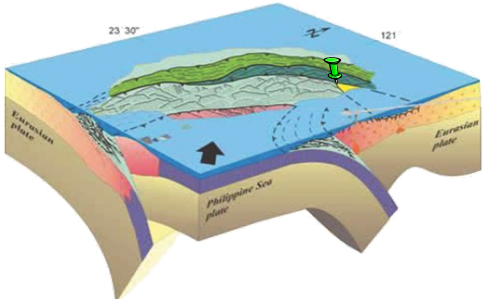

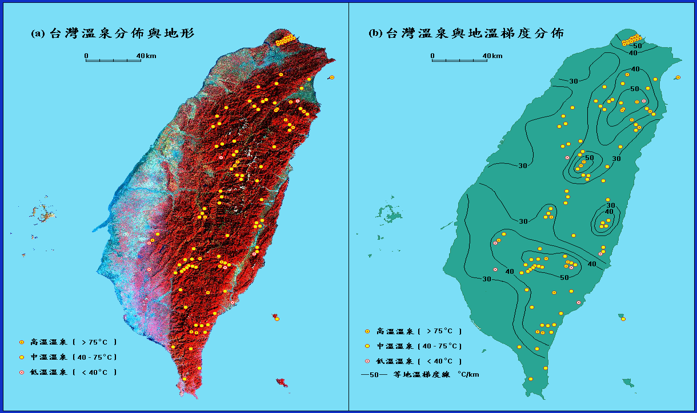

Geothermal Resource in Taiwan

- Geologic and Geothermal Background

-

- Geothermal Systems

-

Type of thermal systems

- VOLCANIC SYSTEMS

- pH Value: 1.0 - 5.0

- SO4=,Cl-

- Reservoir Temperature : 180-280ºC

- Representative site: Datun

- NON-VOLCANIC SYSTEMS

- pH Value: 7.0 – 9.0

- NaHCO3

- Reservoir Temperature : 120-230ºC

- Representative site: Chingshui

- VOLCANIC SYSTEMS

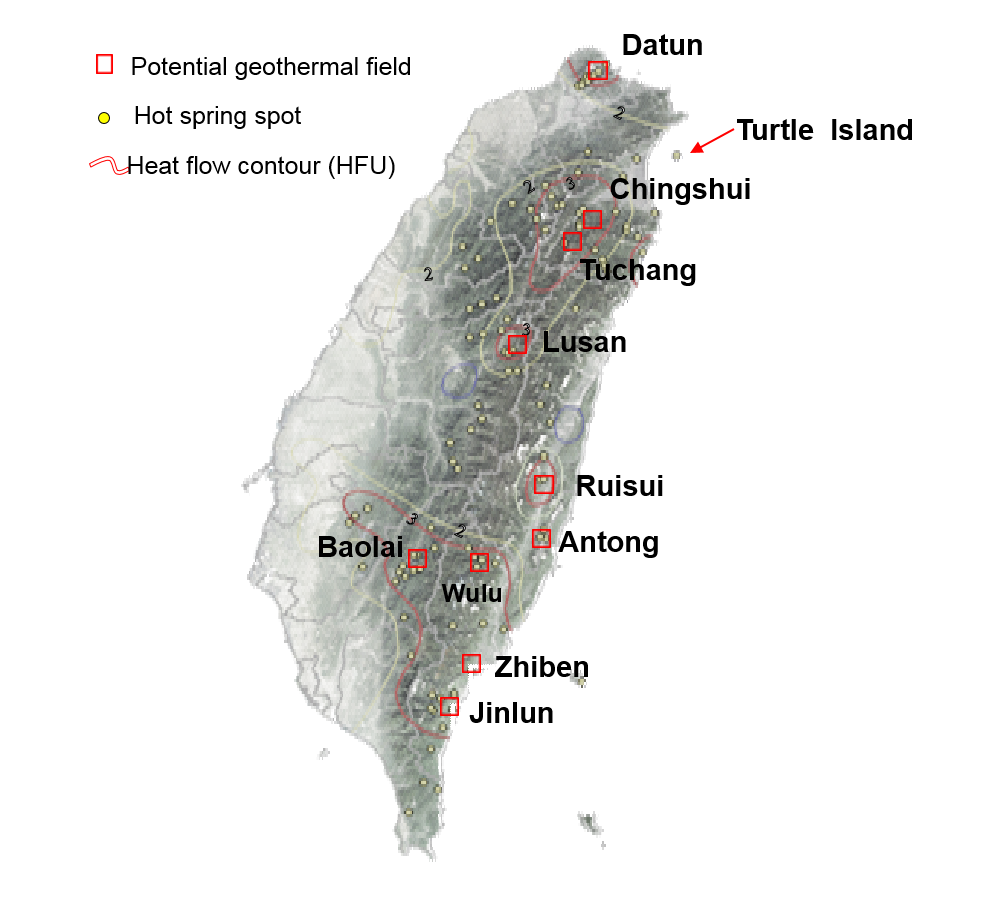

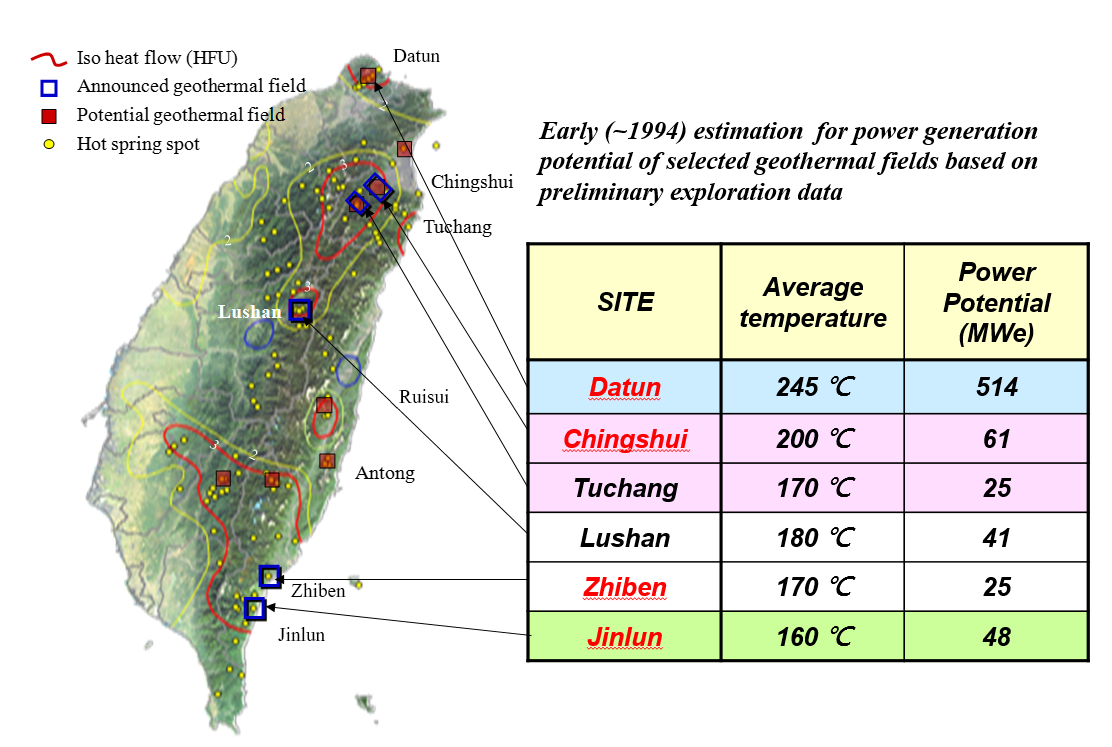

- Potential Geothermal Regions

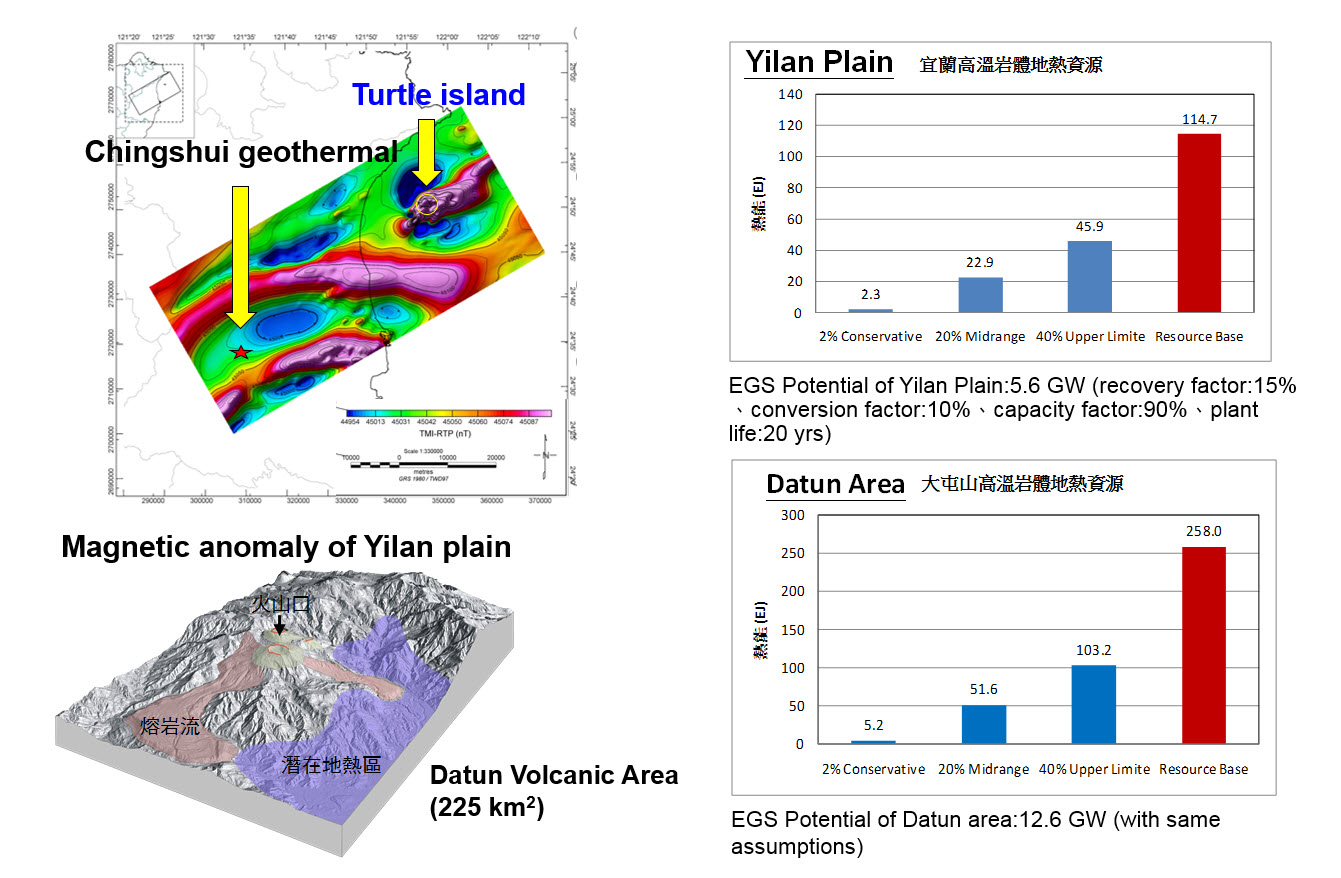

- Potential Areas for EGS Development

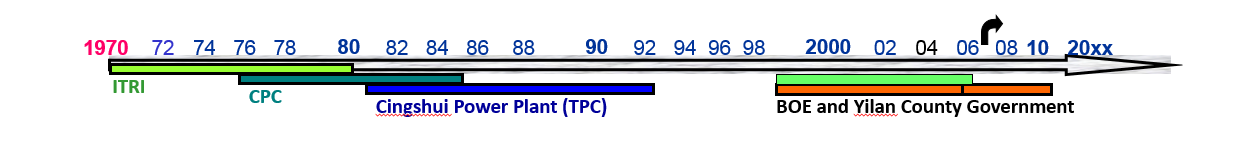

History of Geothermal Development (1966 -1994)

- Geothermal Development (1966-1994)

-

Time Period Location Activities 1966-1972 Datun volcanic region - Exploration

- Multi-purposed application

1972-1993 Chingshui region - Exploration

- Production well drilling

- 3MW Power plant

1973-1975 Hot spring areas around the Island - Field reconnaissance

- Power generation estimate

1980-1984 Mainly Tuchang, Lusan, Zhiben, and Jinlun areas - Limited exploration

- Power generation assessment

1985-1994 Tuchang region - Exploration

- Production well drilling

- 280 kW Binary generation system

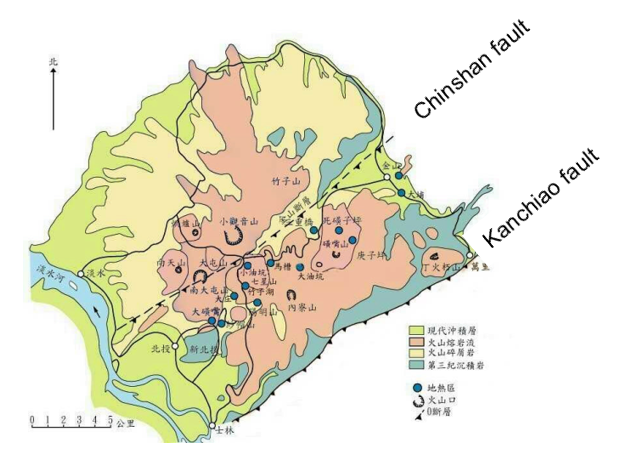

- Geothermal Development in Datun Region

-

- Investigation/exploration between 1966 and 1972.

- 200 km2 of covered area.

- Drilled 82 wells with a total length of 21,188 m.

- Bottomed hole temperature up to 293oC, power generation capacity of 100~500 MW (assessed by the Motor Columbus Consulting Firm, Switzerland).

- Hot water of low pH and high gas content of H2S posed problems to power generation.

- Steam was used for wood drying, greenhouse farming, and animal breeding and cultivation.

- Exploration Wells in Datun Geothermal Area

-

Well depth (m) T_max Q (tph) h (kJ/kg) Yr E-101 519 198 4.4 1112 1967 E-102 629 175 7.4 648 1967 E-103 1000 172 35.6 690 1968 E-201 572 236 3.3 2161 1968 E-202 441 169 2.7 2245 1968 E-203 1005 240 1.8 1881 1968 E-204 577 208 nd nd 1969 E-205 1500 240 26.4 1275 1969 E-206 301 78 nd nd 1969 E-207 768 143 nd nd 1969 E-208 1510 293 32.9 1760 1970 E-209 500 180 3.8 2404 1976 E-210 600 156 nd nd 1970 E-211 361 162 nd nd 1970 E-212 665 258 3.4 2136 1971 E-213 603 123 nd nd 1971 E-214 502 172 nd nd 1972

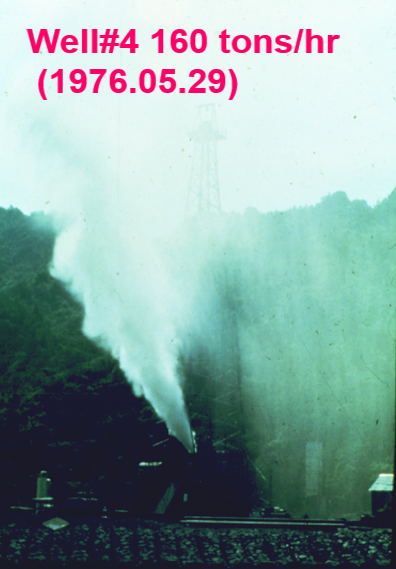

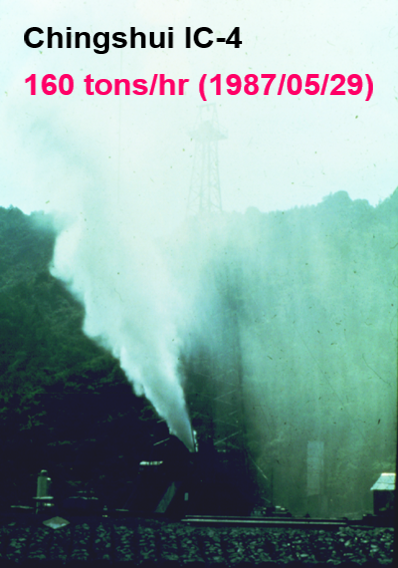

- Geothermal Development in Chingshui Area

-

- Investigation and exploration between 1972 and 1975.

- 100 km2 of covered area.

- Drilled 20 wells with a total length of 8,540 m.

- A 1.5 MWe turbine generator was installed in 1977 by NSC for trial of generating electricity.

- A 3 MW single flash power plant was constructed in April, 1981, and then transferred to TPC for operation in September.

- The power plant was decommissioned in November 1993 due to continuous depletion in well production.

- Geothermal Development in Tuchang Area

-

- Exploration and production drilling between 1985 and 1994.

- A 280 kW binary cycle of power generation installed.

- CO2 was recovered as by-product.

- Served as demonstration of a multi-purposed geothermal application.

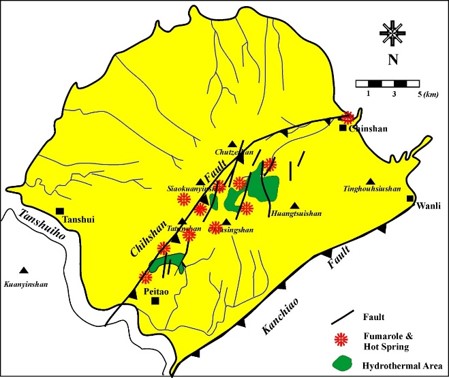

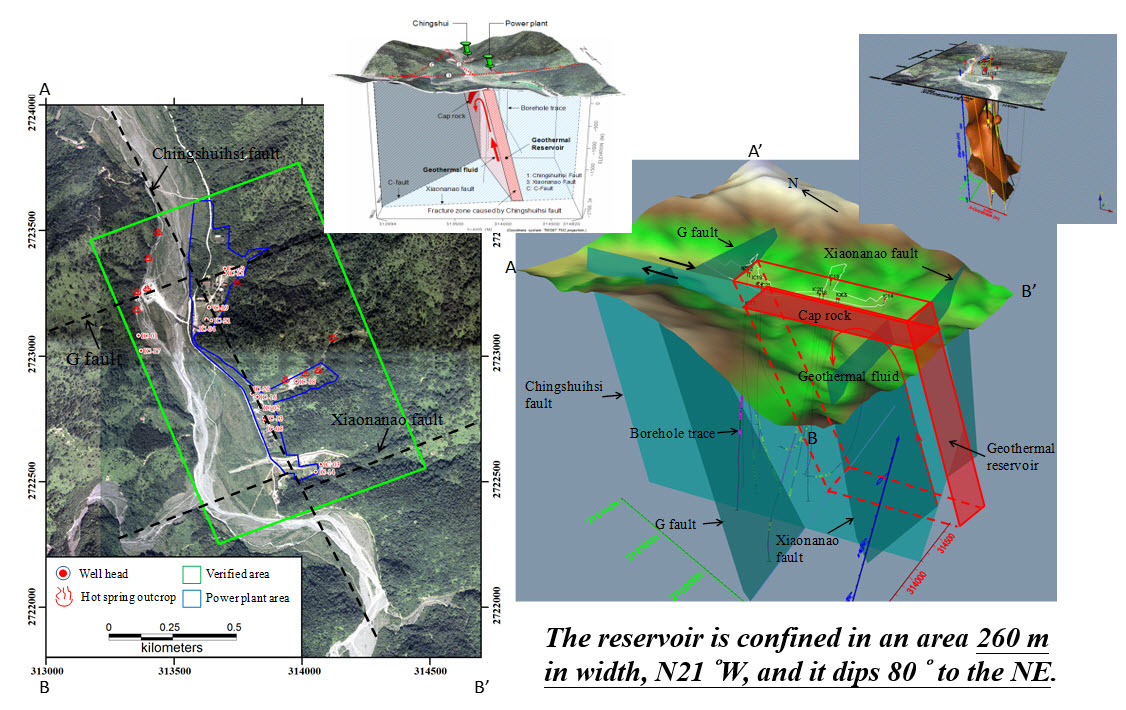

- Chingshui Geothermal Development Area

-

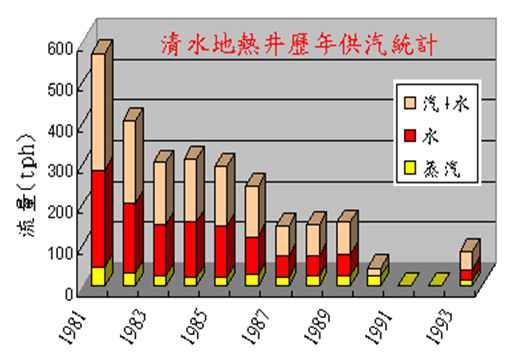

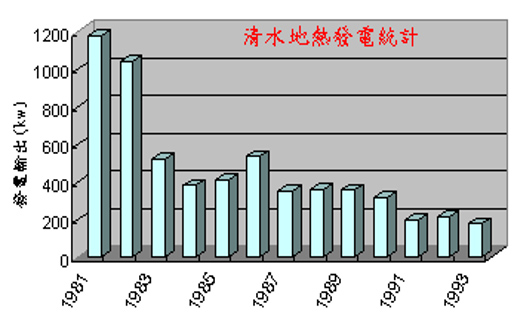

- July 1981 - 3 MWe Power Plant (single-flash) commenced by TaiPower

- Nov. 1993 - decommissioned due to decline in well output

Possible reasons of failure:

Possible reasons of failure:- Inappropriate generation system

- Production decline due to scaling

- No reservoir recharge

Recent Work of BOE and ITRI (2006 – 2019)

- Potential Assessment of Chingshui in 2008

-

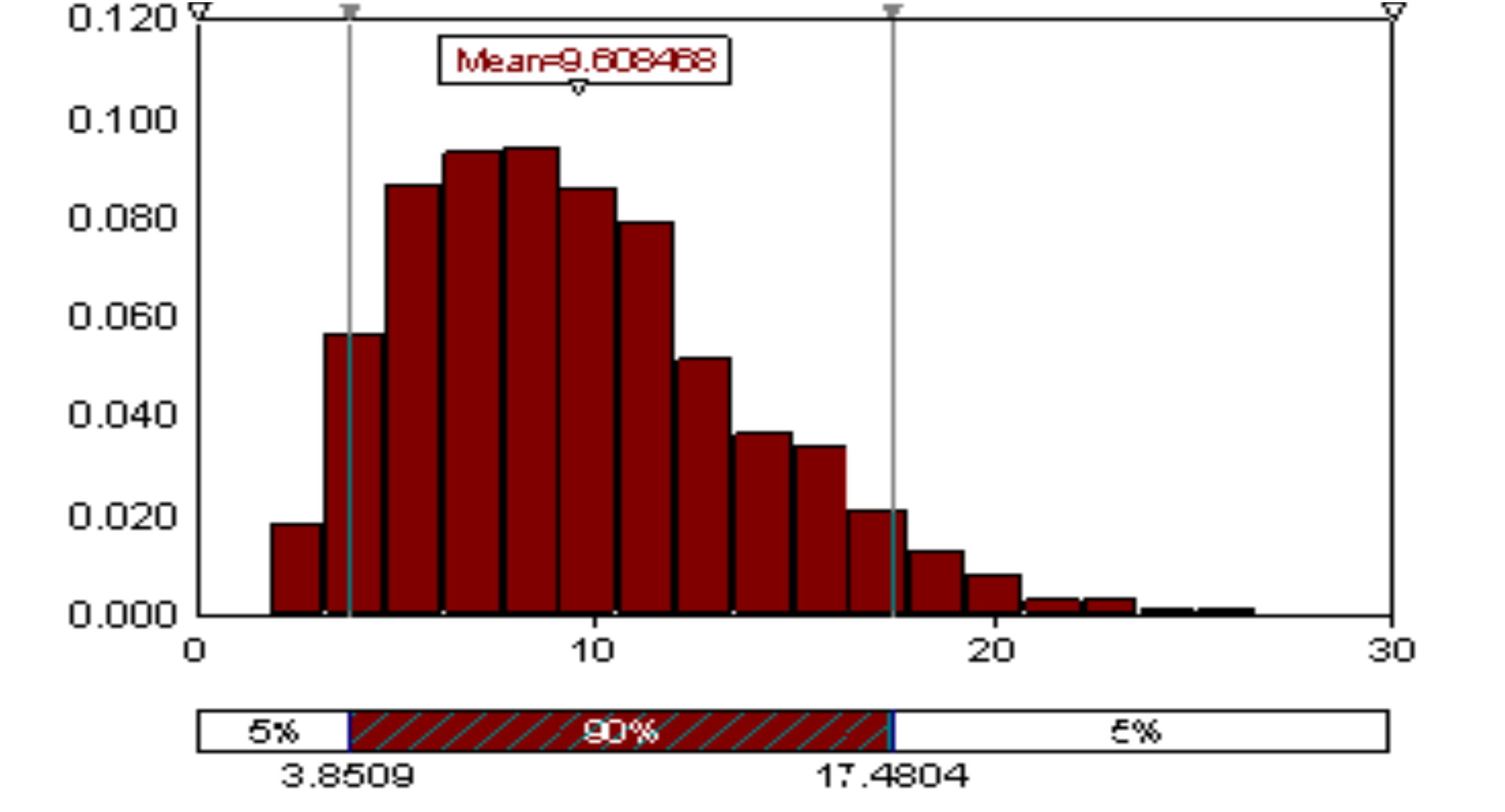

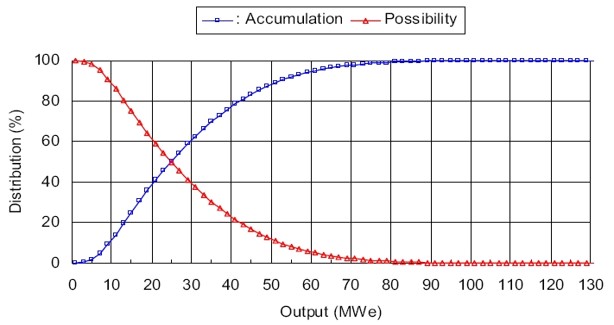

2008 Year

Estimated Potential Parameters adopted Assessor/Methodology 3-9MWe

mean=5.7MWe

plant life: 30yrs90% confidence interval

Volume:0.26/1.5/4.32km3

Temp:160/180/200℃ITRI;

Stored Heat Method with Monte Carlo Simulation9-52MWe

mean=25MWe

plant life: 30yrs90% confidence interval

Volume:0.27/1.12/6km3

Temp:170/200/250℃Foreign Consultant 1;

(Method same as above)4-17MWe

mean=9.6MWe

plant life: 25yrs90% confidence interval

Volume:1.5/4/6.25km3

Temp:190/225/250℃Foreign Consultant 2;

(Method same as above)

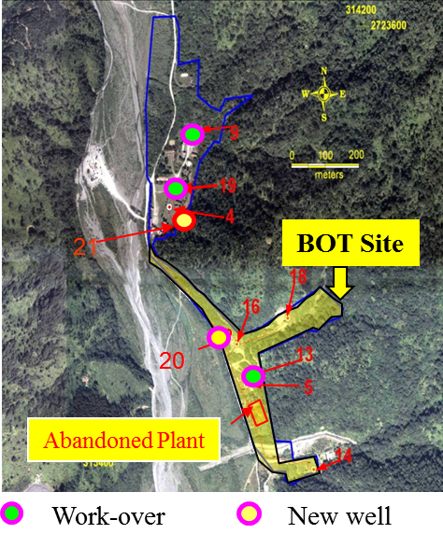

- Updating Conceptual Model of Chingshui

- Work-over and New Well Installation

-

2005~ Now (BOE + ITRI)

- Old well work-over: IC-9、IC-13、IC- 19

- New well installation: IC-20、IC-21

- R&D on well logging, production testing, scaling inhibition, reservoir re-injection, and ORC testing.

- BOT+ROT documents had been announced by Yilan County Government at 2017.7.14.

IC-9:2008 (2079m; 203 ℃)

IC-9:2008 (2079m; 203 ℃) IC-13:2009 (2020m; 217℃)

IC-13:2009 (2020m; 217℃) IC-19:2007 (1227m; 193℃)

IC-19:2007 (1227m; 193℃) IC-20:2006 (503m; 180 ℃)

IC-20:2006 (503m; 180 ℃)

- Demonstration ORC system in Chingshui

-

ITRI’s ORC

ITRI’s ORC Flat Plate HE

Flat Plate HE DHE

DHE Production Well

Production Well

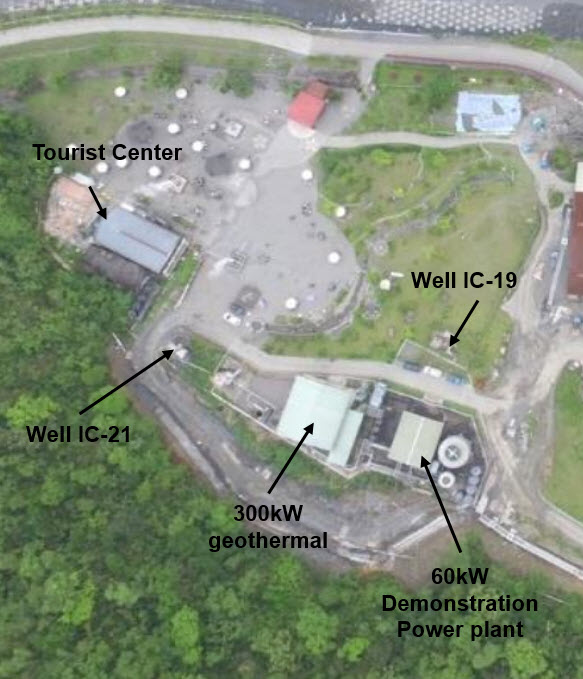

- 300kW geothermal power plant in Chingshui

-

With the help of the BOE, Jieyuan Company built a 300kW geothermal power plant in the Chingshui Geothermal Park, which was officially put into commercial operation at the end of November 2018.

300 kW ORC power generator

300 kW ORC power generator Chingshui Geothermal Park

Chingshui Geothermal Park

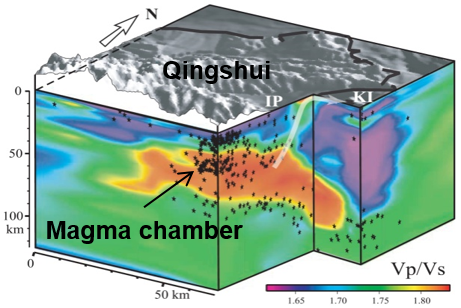

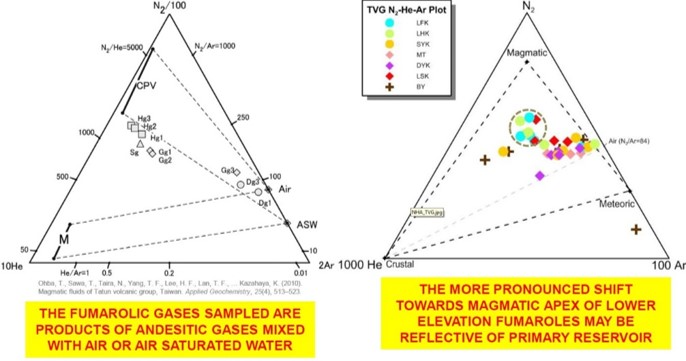

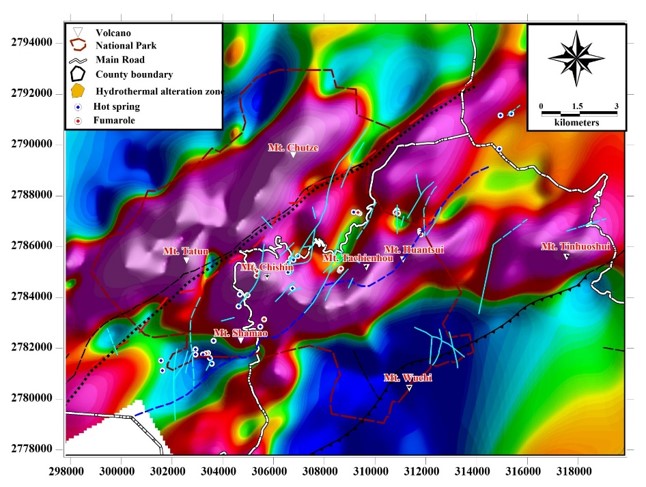

- Datun Volcano geothermal re-exploration

-

- Historical study analysis

- Geology structure identification

- Airborne geophysics

- 3D MT survey

- Gas chemistry

- Initial conceptual model

Fumarole gas chemistry

Fumarole gas chemistry Airborne magnetics

Airborne magnetics 3D resistivity model

3D resistivity model

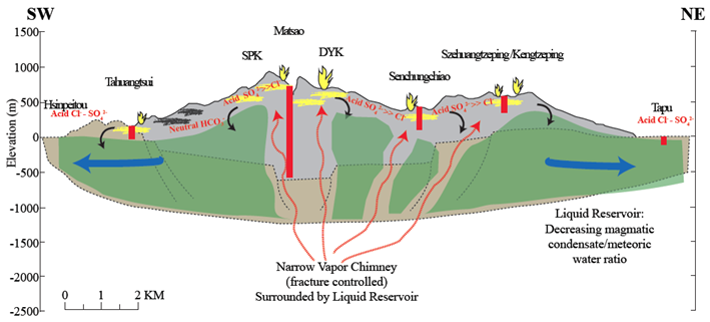

- TVG initial conceptual model

-

- Elevated temperature (>250°C) has been encountered in wells at depths between 1000 and 2000m

- Extensive area of thermal activity

- Significant issues with acidic fluid chemistry

- Presence of multiple eruptive centers creates possibility of multiple shallow intrusions, creating complex thermal structure with smaller upflow zones

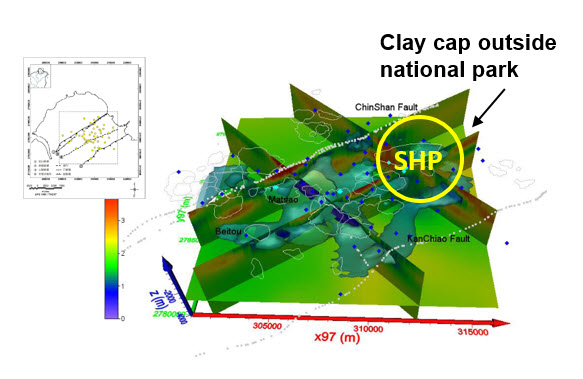

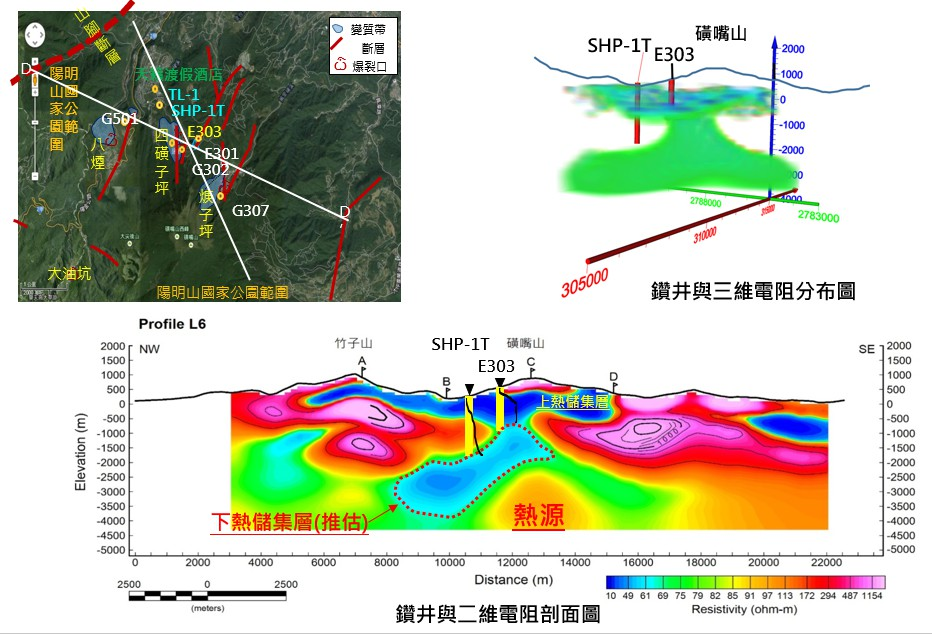

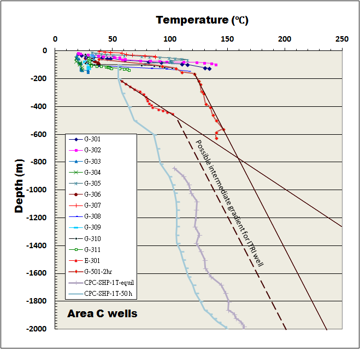

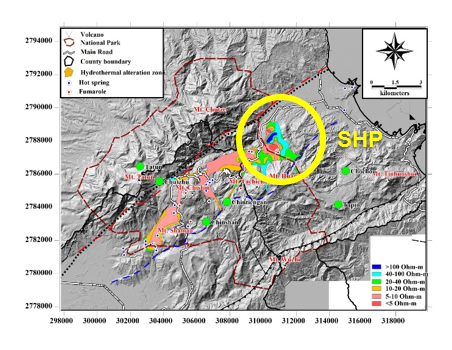

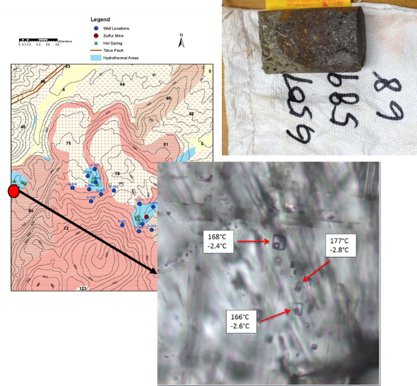

- SHP- geothermal potential site exploration

-

- Low resistivity that represents possible clay cap

- Less sulfur concentration in SHP area

- Calcite vein found at deeper part near SHP

- Outside the national park

- Between two fumarole areas

- 1300 m exploration well is now drilling

Integrated database analysis system

Integrated database analysis system Temperature vs. Depth at SHP area

Temperature vs. Depth at SHP area Location of SHP area

Location of SHP area Fluid inclusion analysis

Fluid inclusion analysis

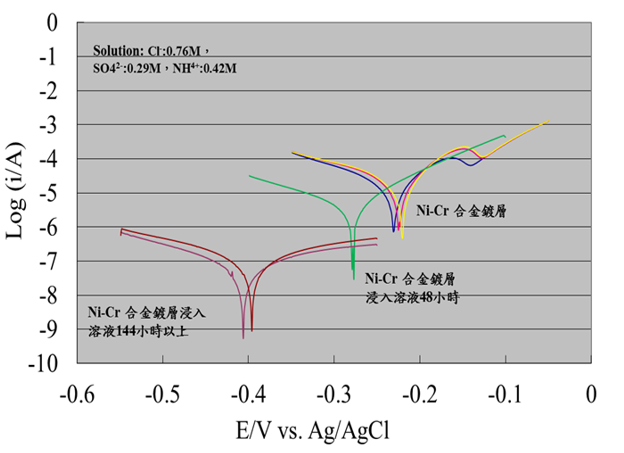

- Anti-corrosion technology

-

- An anti-corrosion coating material has been developed and applied to field over 4000 hrs

- A Ni-Cr plating technology is developed in Lab, though further tests in high acid and high temperature environment are still required.

Anti-corrosion coating field test result

Anti-corrosion coating field test result Tafel plot for Ni-Cr alloy

Tafel plot for Ni-Cr alloy